Precise calculation and reconstitution of peptide vials are crucial for ensuring reproducible research workflows. This guide outlines the steps necessary to ascertain stock solution concentration, execute unit conversions, reconstitute peptides in sterile environments, create working dilutions, store both lyophilized and reconstituted peptides, and address common solubility or aggregation challenges.

Calculating Peptide Concentration

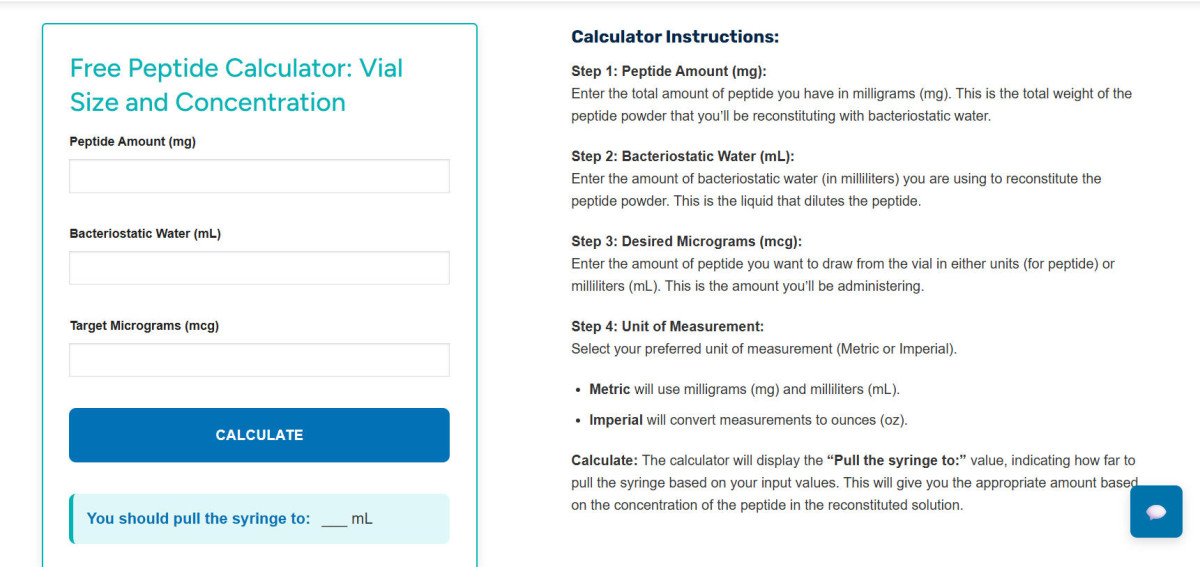

Peptide concentration is defined as the mass divided by the volume:

Concentration (mg/mL) = peptide mass (mg) ÷ diluent volume (mL)

To convert to micrograms per milliliter, multiply mg/mL by 1000. Molarity can be derived using molecular weight:

Molarity (M) = (mg/mL ÷ molecular weight (g/mol)) × 1000

Understanding unit conversions is vital: 1 mg = 1000 mcg, and for U-100 insulin syringes, 1 mL = 100 IU. This enables the accurate translation of target microgram amounts into specific draw volumes.

Unit Conversion Example

A stock solution of 5 mg/mL translates to 5000 mcg/mL. To find the necessary volume for 250 mcg:

Volume (mL) = 250 mcg ÷ 5000 mcg/mL = 0.05 mL

This conversion ensures precise experimental measurements and consistent preparation of stock solutions.

Reconstitution Principles

Reconstitution entails dissolving lyophilized peptide in an appropriate diluent under sterile conditions. The choice of solvent, gentle mixing, and immediate labeling are essential to avoid aggregation or degradation.

Common options for diluents include:

Bacteriostatic water: contains preservatives suitable for multi-use vials.

Sterile water: inert and appropriate for single-use aliquots.

DMSO: effective for dissolving hydrophobic peptides, which should be diluted into an aqueous buffer immediately.

Low percent acid: enhances the solubility of charged peptides.

Step-by-Step Reconstitution

Set up a clean workspace and gather syringes, diluent, labels, and personal protective equipment.

Disinfect the vial septum using an alcohol swab.

Draw the calculated volume of diluent into a sterile syringe.

Inject slowly along the vial wall to minimize foaming.

Gently swirl or flick the vial until the peptide is fully dissolved; avoid vigorous vortexing.

If dissolution is incomplete, allow time for equilibration, consider brief sonication, or add minimal co-solvent.

Label vials with concentration, solvent, date, and any modifications made.

If necessary, aliquot for storage, adhering to cold-chain guidelines.

Preparing Stock Solutions and Dilutions

Begin by preparing a concentrated primary stock, then calculate working concentrations using the formula:

V1 = V2 × (C2/C1)

Mix gently to prevent aggregation, ensuring all aliquots are clearly labeled with concentration, solvent, and date. Serial dilutions provide flexibility while preserving peptide stability.

Storage Guidelines

Lyophilized peptides: Store in a cold and dry environment, typically at -20°C for short-term and -80°C for long-term storage. Protect from light and moisture.

Reconstituted peptides: Refrigerate for short-term use or freeze aliquots at -20°C or -80°C for extended periods. Minimize freeze-thaw cycles and label all aliquots clearly.

Troubleshooting Solubility and Aggregation

Common challenges include incomplete dissolution, precipitation, and aggregation. Suggested solutions include:

Start with gentle swirling and flicking; allow for equilibration time.

If necessary, utilize brief sonication.

For particularly stubborn peptides, cautiously add small amounts of DMSO or low percent acid.

Dilute immediately into an aqueous buffer following dissolution.

If aggregation continues, prepare a new vial and reassess storage conditions.

Preventive strategies include selecting appropriate solvents, adding slowly to buffers, maintaining suitable pH and ionic strength, aliquoting to limit freeze-thaw cycles, and avoiding repeated exposure to room temperature. If aggregation occurs despite these precautions, replacing the peptide is advisable to maintain experimental integrity.

Key Considerations

Double-check all calculations and unit conversions to avoid errors.

Choose syringe types that are appropriate for small-volume measurements to minimize relative error.

Document each step, including solvents and adjustments, to ensure reproducibility.

Practice sterile handling techniques to prevent contamination.

Keep track of stability and clearly label aliquots with concentration, solvent, and date.